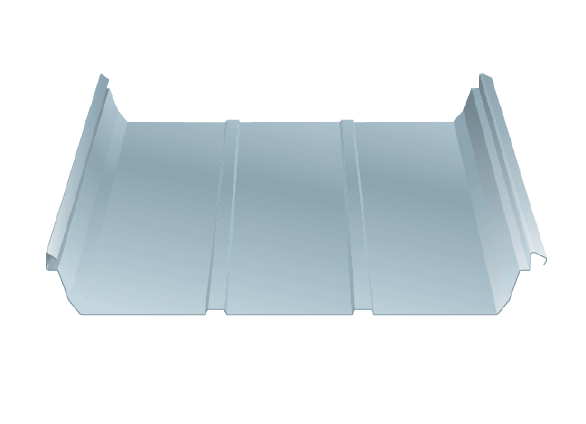

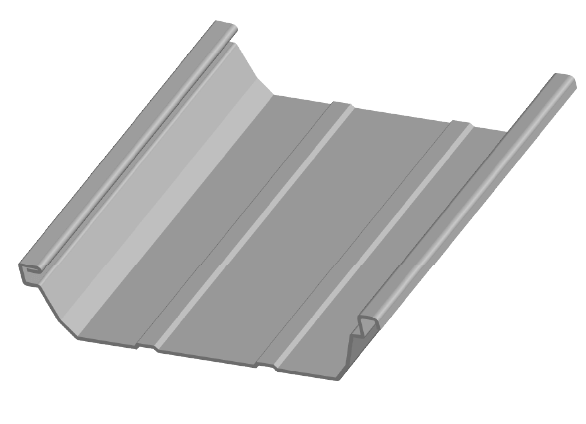

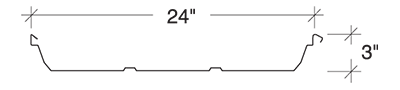

[vc_row css_animation="" row_type="row" use_row_as_full_screen_section="no" type="grid" angled_section="no" text_align="left" background_image_as_pattern="without_pattern"][vc_column][vc_empty_space height="60"][vc_row_inner row_type="row" type="full_width" text_align="left" css_animation=""][vc_column_inner width="1/2"][vc_gallery type="flexslider_slide" interval="3" images="23261,23260" img_size="full" css=".vc_custom_1609341172458{border-bottom-width: 7px !important;border-bottom-color: #009cde !important;border-bottom-style: solid !important;}"][/vc_column_inner][vc_column_inner width="1/2"][vc_column_text]Double-Lok® metal roof panels feature mechanically field-seamed, trapezoidal leg standing seams and creates durable, weathertight building envelopes. This roof system is ideal for new and retrofit applications, and is commonly used for industrial and architectural applications. Double-Lok® panels can attach to sub framing with concealed, interlocking clips that minimize panel penetrations and increases weathertightness.[/vc_column_text][vc_empty_space height="15"][vc_empty_space height="15"][vc_raw_html css=".vc_custom_1647501287133{background-color: #00496d !important;}"]JTNDZGl2JTIwY2xhc3MlM0QlMjJjdXN0b21fY3RhLWJsb2clMjIlMjBzdHlsZSUzRCUyMmJhY2tncm91bmQtY29sb3IlM0ElMjAlMjMwMDQ5NmQlM0IlMjB0ZXh0LWFsaWduJTNBcmlnaHQlMjIlM0UlMEElM0NoMiUyMHN0eWxlJTNEJTIydGV4dC10cmFuc2Zvcm0lM0ElMjB1cHBlcmNhc2UlM0IlMjBjb2xvciUzQSUyMCUyM2ZmZiUzQiUyMHBhZGRpbmclM0ElMjAzMHB4JTIwMzBweCUyMDBweCUyMDMwcHglM0IlMjB0ZXh0LWFsaWduJTNBbGVmdCUyMiUzRVJlYWR5JTIwdG8lMjBTdGFydCUzRiUzQyUyRmgyJTNFJTBBJTBBJTNDaHIlMjBjbGFzcyUzRCUyMmRldmlkZXItYm9yZGVyJTIyJTIwJTJGJTNFJTBBJTNDcCUyMHN0eWxlJTNEJTIyY29sb3IlM0ElMjAlMjNmZmYlM0IlMjBwYWRkaW5nJTNBJTIwMjBweCUyMDMwcHglMjAyMHB4JTIwMzBweCUzQiUyMHRleHQtYWxpZ24lM0FsZWZ0JTIyJTNFRmluZCUyMG91dCUyMGhvdyUyMENlY28lMjBjYW4lMjBoZWxwJTIwYnVpbGQlMEF5b3VyJTIwcHJvamVjdHMuJTNDJTJGcCUzRSUwQSUzQ2ElMjBzdHlsZSUzRCUyMmJhY2tncm91bmQtY29sb3IlM0ElMjAlMjMwMDljZGUlM0IlMjBwYWRkaW5nJTNBJTIwMTBweCUyMDIwcHglM0IlMjB0ZXh0LWFsaWduJTNBJTIwY2VudGVyJTNCJTIwdGV4dC10cmFuc2Zvcm0lM0ElMjB1cHBlcmNhc2UlM0IlMjBmb250LXdlaWdodCUzQSUyMGJvbGQlM0IlMjBjb2xvciUzQSUyMCUyM2ZmZiUzQiUyMGRpc3BsYXklM0ElMjBpbmxpbmUtYmxvY2slM0IlMjBtYXJnaW4lM0ElMjAwJTIwMjBweCUyMDQwcHglMjAzMHB4JTNCJTIwZm9udC1zaXplJTNBJTIwMTZweCUzQiUyMGxpbmUtaGVpZ2h0JTNBJTIwMjBweCUzQiUyMiUyMGhyZWYlM0QlMjIlMkZjb250YWN0JTJGJTIyJTNFQ29udGFjdCUyMFVzJTNDJTJGYSUzRSUwQSUwQSUzQyUyRmRpdiUzRQ==[/vc_raw_html][/vc_column_inner][/vc_row_inner][vc_empty_space height="40"][/vc_column][/vc_row][vc_row css_animation="" row_type="row" use_row_as_full_screen_section="no" type="grid" angled_section="no" text_align="left" background_image_as_pattern="without_pattern"][vc_column][vc_tabsy_tabs tab_containerid="949361148" active_text_color="#303030" active_bg_color="#ffffff" active_br_color="#00b4f0" inactive_text_color="#303030" inactive_bg_color="#ffffff" inactive_br_color="#00b4f0" content_bg_color="#ffffff" content_br_color="#00b4f0"][vc_tabsy_tab title="Product Features" tab_id="1448396812-1-95"][vc_row_inner row_type="row" type="full_width" text_align="left" css_animation=""][vc_column_inner width="1/2"][vc_column_text]Dimensions: 24″ and 18″ wide by 3″ deep

Slope: 1/4:12 or greater; When using the fixed clip we recommend for double slope buildings 200′ wide or less and single slope buildings 100′ wide or less. (May vary upon extreme weather conditions.)

Panel Attachment: Concealed Fastening System

Gauges: 24, 22

Facings: Smooth (standard); Embossed (optional)

Finishes: Galvalume Plus®, Signature® 200, Signature® 300

Rib Spacing: N/A

Thickness: N/A

Lengths: 55′ maximum is standard but longer lengths available by special request

Reveal: N/A

Fasteners: Concealed fastening system with floating clips. The clips are available as floating. Two different clip heights are available to allow for insulation

Usage: New and retrofit roof applications[/vc_column_text][/vc_column_inner][vc_column_inner width="1/2"][/vc_column_inner][/vc_row_inner][/vc_tabsy_tab][vc_tabsy_tab title="Features & Benefits" tab_id="1448473818810-3-1"][vc_row_inner row_type="row" type="full_width" text_align="left" css_animation=""][vc_column_inner width="1/2"][vc_column_text]

Features

[/vc_column_text][/vc_column_inner][vc_column_inner width="1/2"][vc_column_text]

Benefits

[/vc_column_text][/vc_column_inner][/vc_row_inner][vc_row_inner row_type="row" type="full_width" text_align="left" css_animation=""][vc_column_inner width="1/2"][vc_column_text]Panel penetration is eliminated over the entire building envelope other than at the end laps and panel ends which are connected by a compression joint[/vc_column_text][/vc_column_inner][vc_column_inner width="1/2"][vc_column_text]Assurance of a weathertight building envelope[/vc_column_text][/vc_column_inner][/vc_row_inner][vc_row_inner row_type="row" type="full_width" text_align="left" css_animation=""][vc_column_inner width="1/2"][vc_column_text]Factory notched at both ends with pre-punched holes[/vc_column_text][/vc_column_inner][vc_column_inner width="1/2"][vc_column_text]Field installation efficiency is maximized with installation allowed from either end of building or on both sides simultaneously.[/vc_column_text][/vc_column_inner][/vc_row_inner][vc_row_inner row_type="row" type="full_width" text_align="left" css_animation=""][vc_column_inner width="1/2"][vc_column_text]End laps feature a 16 gauge backup plate with pre-punched holes[/vc_column_text][/vc_column_inner][vc_column_inner width="1/2"][vc_column_text]Allows solid connection at end laps plus proper fastener spacing. Pre-punched holes improve installation; assure proper panel placement.[/vc_column_text][/vc_column_inner][/vc_row_inner][vc_row_inner row_type="row" type="full_width" text_align="left" css_animation=""][vc_column_inner width="1/2"][vc_column_text]Fewer exposed fasteners (by 80%) than traditional side lap panels[/vc_column_text][/vc_column_inner][vc_column_inner width="1/2"][vc_column_text]Increased weathertightness[/vc_column_text][/vc_column_inner][/vc_row_inner][vc_row_inner row_type="row" type="full_width" text_align="left" css_animation=""][vc_column_inner width="1/2"][vc_column_text]Air infiltration and water penetration tests under IAS E283 and E331 methods performed on side lap panels[/vc_column_text][/vc_column_inner][vc_column_inner width="1/2"][vc_column_text]Assures specifiers of minimal air infiltration and water penetration[/vc_column_text][/vc_column_inner][/vc_row_inner][vc_row_inner row_type="row" type="full_width" text_align="left" css_animation=""][vc_column_inner width="1/2"][vc_column_text]Signature® 300 paint system[/vc_column_text][/vc_column_inner][vc_column_inner width="1/2"][vc_column_text]25-year finish warranty[/vc_column_text][/vc_column_inner][/vc_row_inner][vc_row_inner row_type="row" type="full_width" text_align="left" css_animation=""][vc_column_inner width="1/2"][vc_column_text]Tall or short clips[/vc_column_text][/vc_column_inner][vc_column_inner width="1/2"][vc_column_text]Maximizes insulation systems options including 1” thermal spacers at the purlins[/vc_column_text][/vc_column_inner][/vc_row_inner][vc_row_inner row_type="row" type="full_width" text_align="left" css_animation=""][vc_column_inner width="1/2"][vc_column_text]Panel side laps feature a factory applied sealant[/vc_column_text][/vc_column_inner][vc_column_inner width="1/2"][vc_column_text]Facilitates weathertight construction and ease of installation[/vc_column_text][/vc_column_inner][/vc_row_inner][vc_row_inner row_type="row" type="full_width" text_align="left" css_animation=""][vc_column_inner width="1/2"][vc_column_text]UL 90 and FM rated[/vc_column_text][/vc_column_inner][vc_column_inner width="1/2"][vc_column_text]Lower insurance costs[/vc_column_text][/vc_column_inner][/vc_row_inner][vc_row_inner row_type="row" type="full_width" text_align="left" css_animation=""][vc_column_inner width="1/2"][vc_column_text]Optional product and weathertightness warranties[/vc_column_text][/vc_column_inner][vc_column_inner width="1/2"][vc_column_text]Adds to customer confidence[/vc_column_text][/vc_column_inner][/vc_row_inner][/vc_tabsy_tab][vc_tabsy_tab title="Color Data" tab_id="1448396812-2-1"][vc_column_text]Ceco Color Chart [/vc_column_text][/vc_tabsy_tab][vc_tabsy_tab title="Specifications" tab_id="1448396935193-2-2"][vc_row_inner row_type="row" type="full_width" text_align="left" css_animation=""][vc_column_inner width="1/2"][vc_column_text]Double-Lok Metal Roof Panel CSI Specifications

Double-Lok Metal Roof Panel Product Data Sheet[/vc_column_text][/vc_column_inner][vc_column_inner width="1/2"][vc_single_image image="16333" img_size="full" qode_css_animation=""][/vc_column_inner][/vc_row_inner][/vc_tabsy_tab][vc_tabsy_tab title="Installation Manuals" tab_id="1464376089752-4-9"][vc_column_text]Double-Lok® Metal Roof Panel Manual[/vc_column_text][/vc_tabsy_tab][vc_tabsy_tab title="CAD Details" tab_id="1481140502075-5-5"][vc_column_text]View Double-Lok Metal Roof Panel CAD Details[/vc_column_text][/vc_tabsy_tab][/vc_tabsy_tabs][vc_empty_space height="60"][vc_column_text]

RELATED PROJECTS

[/vc_column_text][vc_empty_space height="40px"][/vc_column][/vc_row][vc_row css_animation="" row_type="row" use_row_as_full_screen_section="no" type="full_width" angled_section="no" text_align="left" background_image_as_pattern="without_pattern"][vc_column width="1/2"][vc_single_image image="24640" img_size="full" alignment="center" onclick="custom_link" qode_css_animation="" link="https://www.cecobuildings.com/gallery/?mg_items=riley-brothers-construction"][vc_empty_space height="20px"][vc_column_text css=".vc_custom_1689625180650{padding-right: 15px !important;padding-left: 15px !important;}"]

Builder: Piotter Construction

Location: Morris, MN

[/vc_column_text][vc_empty_space height="20px"][ult_buttons btn_title="VIEW PROJECT" btn_link="url:https%3A%2F%2Fwww.cecobuildings.com%2Fgallery%2F%3Fmg_items%3Driley-brothers-construction" btn_align="ubtn-center" btn_title_color="#ffffff" btn_bg_color="#009cde" icon_size="32" btn_icon_pos="ubtn-sep-icon-at-left" btn_font_style="font-weight:bold;"][/vc_column][vc_column width="1/2"][vc_single_image image="24616" img_size="full" alignment="center" onclick="custom_link" qode_css_animation="" link="https://www.cecobuildings.com/gallery/?mg_items=radiant-church"][vc_empty_space height="20px"][vc_column_text css=".vc_custom_1689625366687{padding-right: 15px !important;padding-left: 15px !important;}"]

Builder: Nett Construction

Location: Bradenburg, KY

[/vc_column_text][vc_empty_space height="20px"][ult_buttons btn_title="VIEW PROJECT" btn_link="url:https%3A%2F%2Fwww.cecobuildings.com%2Fgallery%2F%3Fmg_items%3Dradiant-church" btn_align="ubtn-center" btn_title_color="#ffffff" btn_bg_color="#009cde" icon_size="32" btn_icon_pos="ubtn-sep-icon-at-left" btn_font_style="font-weight:bold;"][/vc_column][/vc_row]