The Grass is Greener: Metal Construction & Cannabis Cultivation

Posted on September 14, 2021 by Ceco Building SystemsOut From Underground

For the majority of the last century, cannabis cultivation has happened in secret. But now, with cannabis legalized or at least decriminalized in 39 US states, growers are coming out of the woodwork. Public support for universal legalization is overwhelming, and in states where medical or recreational legalization has been successful, business is booming – up to an estimated $61 billion. What’s more, the market is predicted to grow by a compound annual rate of 21% year over year.

Growth Spurt

Both the medical and recreational cannabis industries are rushing to supersize their operations. Demand is suddenly through the roof, and supply must race just to keep up. Yet cannabis is far from commodity status. Competition is fierce to develop the strongest varieties – or to isolate strains and compounds with a growing list of different desired effects. Growers nationwide are looking to establish their competitive edge – or break through with a new product no one else has yet dreamed up.

A Highly Regulated Environment

That edge begins with the environment in which the cannabis plants are grown, and more often than not, growers choose indoor facilities. Cultivating market-busting cannabis requires absolute control of every environmental condition. A nearly tropical environment must be created and regulated indoors. Temperature must be maintained, regardless of whether it’s a blistering hot summer day or snow is piling up on the roof. Humidity and air movement also need to be precisely managed, giving enough moisture to plants while inhibiting bacterial or mold growth. Powerful lighting and treated watering cycles provide artificial cues to the plant as to the season, determining its phase of development and growing cycle – from seedling to growth to fruiting.

Micromanagement

But that’s just the start, because each room – and often each strain – requires slightly different atmospheric conditions and control over those conditions. Within a single grow facility, multiple different temperatures, varying levels of humidity and stages of growth likely exist next-door to each other. Cannabis cultivation also requires extensive ceiling-mounted equipment: from lighting systems, HVAC and MEP infrastructure to fire protection, mechanical, plumbing, electric, condensing units, watering systems and indoor blowers. This all increases the collateral load significantly.

All this amounts to considerable demands on the building, its structure, performance characteristics, durability and cost. Luckily, Ceco’s vast experience in metal construction is ideally suited to take on every demand – and to outperform them.

A Match Made in Heaven

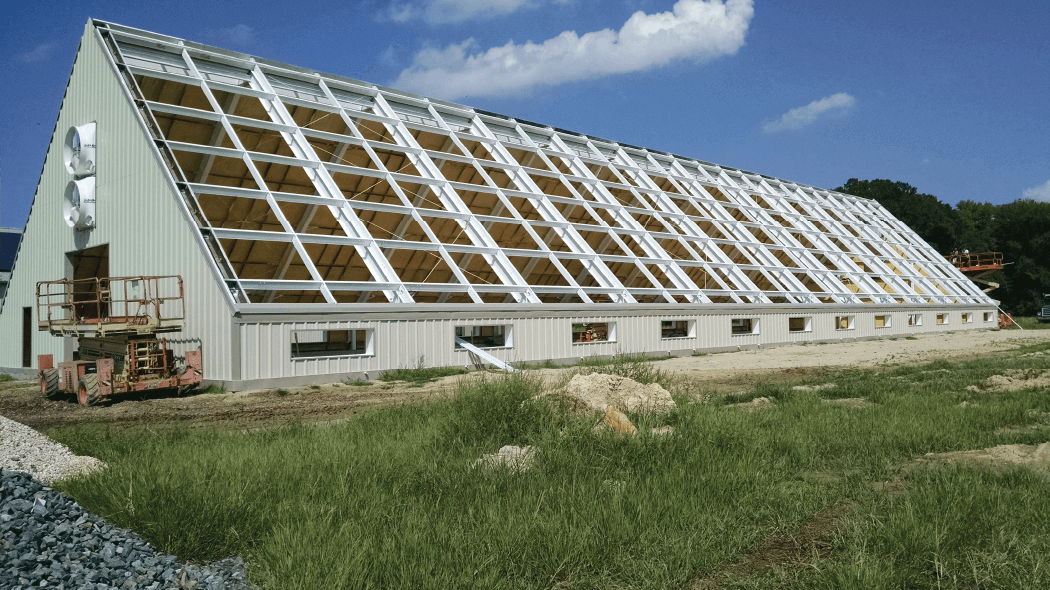

Metal buildings – and insulated metal panel (IMPs) construction, in particular – are the perfect match for cannabis cultivation. They can not only handle the consistent intense humidity required in the cultivation process, but also extremes of cold, heat, rain and drought. IMPs provide air, water and vapor barrier in a single product installed in a single step. They also include a foamed-in-place insulated core. That means instead of multiple trades installing multiple layers of the building envelope, a single trade can do it in a single step, reducing time, cost, and exposure – allowing expedited dry-in times so interior trades can move in sooner.

Materials arrive on site pre-punched, drilled, and ready for assembly, reducing erection time by approximately 33% compared to other methods. In fact, it has been estimated that a crew of four can erect as much as 5,000 square feet of IMPs in a single eight-hour shift.

Energy Offset

From water to heating and cooling, the energy costs of running an indoor grow facility are considerable. But metal and IMP construction help offset those costs by significantly reducing heating and cooling costs through exceptional insulating properties and thermal uniformity.

IMPs provide other features, as well. Metal doesn’t support the growth of mold and is resistant to rust and decay, while sealing off the building so well it’s virtually airtight – keeping out pests, rodents and contaminants alike. Special drainage systems can be included, as well as recessed spaces in aisles for water faucets and easy-to-clean wall finishes – including specially formulated systems designed to stand up to regular, high-pressure washes. Metal construction is also perfectly suited to handle the increased collateral load cannabis cultivation requires.

Filling The Footprint

Making the most of every square foot of a building’s footprint is critical to maximizing a grow operation’s profit margin, and Ceco helps with that as well. The Ceco Long Bay® System allows for column-free interiors and large, unobstructed, clear span space to support crops, water storage, processing facilities, product storage, and more. Likewise, the addition of mezzanines and lofts can double the capacity of a building footprint. As the business grows, metal buildings can scale alongside, ready for a boost in demand to be matched by a boost in size.

Custom Fit

Ceco metal buildings are anything but pre-engineered, with all components custom-designed and made to order. When you contact a Ceco representative near you, we’ll make time to consult with you about site selection, topographic conditions, as well as both interior and exterior design. The building will be custom engineered to meet your facility requirements and local building codes. If you prefer, we can provide the products and handle construction. Trusting your project to a single source of responsibility means you know precisely what to expect – and precisely who to call should you ever encounter a problem. That’s the accountability and partnership Ceco is built on.

Set it & Forget it

Once the building is erected, it will be virtually maintenance free. Metal walls and sloped metal roofing are self-cleaning – requiring nearly no upkeep, which further reduces your operating costs. Still, excellent warranties are available for your Ceco products, just in case.

Don’t let the others get ahead. Get in touch with a nearby Ceco representative today to get your cannabis cultivation project on the books. The sooner you do, the sooner you can plant, harvest and see your products hit the shelves!