The Advantages of a Long Bay® Roof System

Posted on June 26, 2018 by Ceco Building SystemsA common need in manufacturing, warehouse, distribution and large retail buildings such as supermarkets is large, open spaces with minimum interruptions by columns. Often, in these cases, a steel structural frame is used with the roof supported by open web steel bar joists. Increasingly, a superior alternative to bar joists is being employed in the form of fabricated long bay trusses known as the Long Bay® roof system. It provides building designers, installers and owners with many noticeable advantages.

Engineering Advances

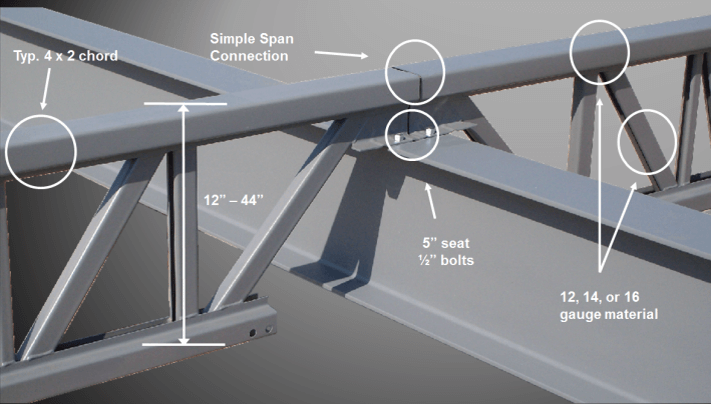

The Long Bay® truss systems are cold formed from 12 and 14 gauge steel to create the chord and web members – the same process as other metal structural members such as girts and purlins. The shop fabricated Long Bay® trusses are engineered to be stronger, wider and lighter than conventional bar joists. The resulting system is very linear and straight with improved performance particularly in the horizontal or weak axis. Commonly ranging in depth between 12 to 44 inches, they can span up to 70 feet, with a sweet spot at 60 feet. Longer spans mean fewer columns and fewer foundations thus simplifying design and reducing costs. Long Bay® trusses can also be designed to be used as a spandrel box beam to eliminate intermediate columns and beams in side walls or tilt-up construction.

Installation Efficiencies

There are several advantages for installers when using long bay systems. First, it is a truly bolted system with no field welding involved. Two ½” bolts are all that is needed on the end of each truss to secure them directly to the primary structure. Notably, there are no torque requirements on the bolts as would be common in other systems. Second, there is little or no bridging required. Conventional bar joists often require 7 – 8 rows of bridging on both the top and bottom, for a total of about 15 rows. Long Bay® trusses eliminate the need for top chord bridging and require only minimal bottom chord bridging, even when standing seam roofing is used. This produces a huge savings in time to erect and install the roof, on the order of at least 25 percent or more in labor savings. Third, the 4-inch top chord provides a continuous, solid area for attaching roofing. That reduces the potential for fasteners to miss the top chord or end up between the angles of bar joist. More solid attachment means the roof system performs as intended. Finally, it is possible to bolt and connect a series of long bay trusses on the ground and lift them up using two cranes to settle them into place. This can make the installation process easier, faster, and more economical.

Scheduling Advantages

Long Bay® systems are made and provided by a metal building manufacturer. Conventional bar joists are often provided by a separate company than the supplier of other metal building products. The notable distinction is that the schedule for the production and delivery of bar joists is controlled by a third party company while the schedule for producing Long Bay® systems is controlled directly by the metal building manufacturer. While this aspect alone often produces shorter lead times, it also means they can be shipped as part of a single-source metal building package to simplify the total construction schedule.

Improved Finished Appearance

Many buildings with large open areas are designed with the intention of keeping the structure open and exposed to view. In that regard, Long Bay® provides a very clean and neat visual appearance, particularly compared to bar joists with lots of bridging. Further, the thicker chord members provide a place to conceal wiring, piping and other needed items. The Long Bay® system also has optional accessories available for a similarly neat installation of sprinklers, mechanical, lighting, and other items all without the need for field welding. This system works particularly well with Early Suppression Fast Response (ESFR) sprinklers used in many warehouses.

To find out more about ways to incorporate a Long Bay® system into your metal buildings, contact your local Ceco representative. You can also find more information on the Long Bay® system here.